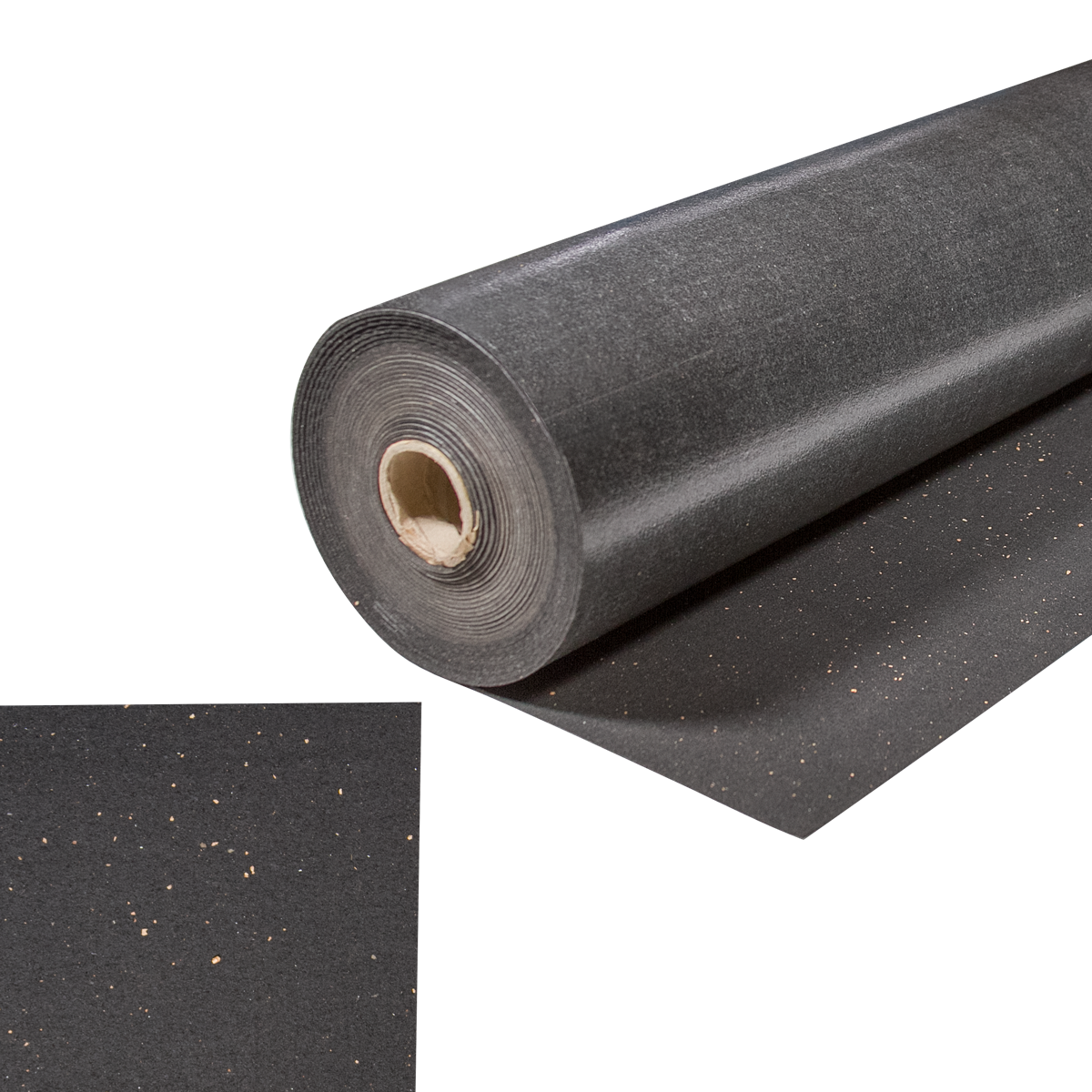

QTscu ( Sound Control Underlayment) or QT Sound Insulation is a flat, resilient rubber underlayment made from a formulation of high quality post consumer recycled rubber granules encapsulated in a wear and water resistant elastomeric network with multiple colored reprocessed ColorMill EPDM rubber. QT Acoustic Insulation & QT Sound Control Underlayment Floor Preparation & Maintenance Products.Some products out there can be floated but not glued down and vice versa. “Everybody is looking for a product that’s universal, that you can use for glue down, floating, etc. We were told that lvt gets an IIC of 35 without an underlayment, and the magic number people are looking for is at least 50.”Ĭummings cautioned that a versatile underlayment should be chosen when working with lvt. Vinyl sounds fine being walked on in the room, but we have found that it transmits the sound right through the floor.

For LVT, the underlayment is needed so your neighbors downstairs won’t hear you walking across the floor. “You put underlayment under laminate so it sounds more like hardwood. However, these products are used for two different reasons. According to Andy Stafford, Healthier Choice marketing manager, his company’s acoustical underlayment can be used under floating, nail-down and glue-down installations.īob Cummings, Pak-Lite Inc.’s marketing manager, said that both vinyl and laminate flooring need underlayments to help with noise control. The entangled net materials can be combined with features that enhance performance with muffling technology.”ĭevin added that it is important to find out whether an underlayment will hold up after being installed, or compress over time, which will affect how well the product performs.Ĭhoose what you need. “Only assemblies are tested prior to installation to help assure that complaints are minimized. Jim Keene, president and owner of Keene Building Products, noted that his company’s QUIET QURL brand has undergone more than 600 tests. “End users want the guarantee that the product will meet strict building codes, as well as provide a quiet, noise-free environment to satisfy the occupants.” Tony Wert, business unit manager for ECORE International’s QT sound isolation underlayments, said the sound control ratings for his company’s products are backed by more than 200 independent tests. Make sure the lab test matches your floor/ceiling assembly, or you will not get the same IIC result.” Most quality underlayment companies will have more than one lab test. “There are many companies that are selling thin 2-3mm foam-based underlayment products claiming IIC ratings of 72, but contractors and installers must first ask if the company has a background in acoustics, and then ask for the lab IIC test. for Sound Seal’s Impacta Flooring division, said to be wary of high IIC ratings that serve mostly as a marketing tool. Bill Devin, national sales & technical mgr. Think of impact sound as the neighbors downstairs hearing footfalls in the apartment above them, and sound transmission as catching bits of talk and music from a loud radio in the other room. STC, on the other hand, measures the transmission of sound through a building. IIC is the rating of impact sound as it moves through a floor/ceiling assembly. First, it is important to understand the differences between IIC and STC. Here are some tips for choosing the proper product. However, choosing the proper noise control system is about more than just looking at numbers on a product spec sheet. When it comes to sound control, most installers and contractors know that the finished installation will need to meet certain minimum IIC (Impact Isolation Class) and STC (Sound Transmission Class) requirements, and that’s usually where their knowledge ends.

0 kommentar(er)

0 kommentar(er)